No matter what kind of business you run, small or big, a tea shop or multinational company, you need to have something to sell to the customer and you can only do that if you purchase the goods, raw materials and other items needed for the final product, service or deliverable. Every business needs to think about procurement to provide a product or service.

What Is The Procurement Process?

The process in which a business spends time and money acquiring goods and services, from several select vendors and suppliers. Most often this is seen when a business gets raw materials from these sources to create a finished product to sell to the customer. This process, though common for all businesses, is not a uniform one. It will vary for each industry and each business, depending on the nature of the products/services being created for the customer and the needs of the business itself.

Why Is An Effective Procurement Process Important?

It is a crucial part of a business’s operations for a few important reasons. Procurement is known for being a cost-effective way for a company to purchase and acquire certain goods or services from external vendors. This lends itself to higher profit margins for one. The second reason is that it helps the business find the right vendors and sources for procuring things, this ensures the company can keep a close eye on the quality and nature of the source giving the finished product/service more quality control.

Apart from saving cost and giving the business better control over the quality, it also helps the brand establish business relations and build a vast network with these vendors and suppliers. This means that it keeps the company in the loop when it comes to the goings-on in the market. The first to know of any changes in the trends, prices, and customer preferences are the suppliers and vendors. Having this knowledge and building a good working relationship with them helps keep the entire process moving as efficiently and as productively as possible.

‘‘

To make the most of the procurement process it is important to note that it is not a standalone concept. It works in tandem with logistics and the supply chain of a business.

The Connection Between Procurement, Logistics And Supply Chain Management

Procurement is an intricate network of vendors with several stages that account for many things such as acquiring logistics, building connections with manufacturers and vendors, negotiating the prices, invoicing, shipping notifications, placing orders and tracking receipts.

That being the case, it is still just a small part of a larger process that is known as ‘supply chain management’. Supply chain management is the movement or flow of goods or services throughout the organisation. This includes the procurement of the raw materials or primary services from vendors, the storage and/or refinement stage, shipping to consumers and so on. In essence, it is the active streamlining of the business’s supply and distribution side to maximize the value brought to the customer.

‘Logistics’ is the smallest link on this massive chain, but still important. It refers to the actual moving of products or services from the point of origin to the point of consumption by the customer. So, for example, if a business sells eggs, it needs to get the eggs from the farm to the customer. To do that it will need trucks, crates and drivers to get those eggs from point A-to-B. These physical assets are what is known as logistics and they come under the process of procurement, as one part of the overall procurement process.

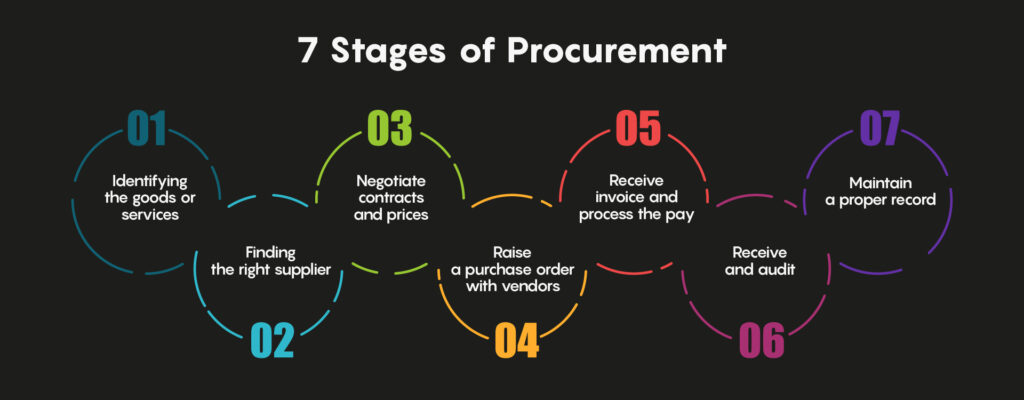

The 7 Stages Of Procurement

Stage 1: Identifying the goods/services

From the outset, a business needs to be aware of what is needed to function smoothly. That is why, before initiating the procurement process, the company needs to identify two things the internal and external goods or services needed. The internal is everything that the company will need to run the business. The external refers to the things that will be sold to the consumer. Identifying these things also helps identify the budget for the operations.

Stage 2: Finding the right supplier

A good brand needs good sources to bring them high-quality materials. This stage is all about finding those sources. While sourcing potential vendors may seem straightforward, there are a few key things to look out for. During the evaluation, check and compare different pricing for services, the quality of service, the vendor’s reputation as a source as well as the warranties and guarantees that are provided by the vendor.

Stage 3: Negotiate contracts and prices with the selected suppliers

This is exactly what it sounds like negotiating with the vendors until all parties can settle on a fixed price for services and signing a contract for the same. The contract plays an important role as it sets the tone for the delivery time, the job description, the number of materials needed and so on. Another important factor in this, is that it also takes care of the ‘enablement of logistics’ for the entire process. That is to say, if you were to organise and procure logistics for the movement of goods and services from start to finish, this is the stage in which you should take care of that.

Step 4: Raise a purchase order with vendors

This is the part of the process where the actual purchasing of goods and services happens. Once the purchase order is looked-over and finalised by the finance department, it is sent to the vendors. In the special case that there were no contracts signed at the beginning, these purchase orders are considered as legally binding documents.

Stage 5: Receive invoice and process the pay

After the supplier gets the purchase order from the company, an invoice with the price for that particular goods/service is sent back. The procurement team then has to match the invoice to the purchase order and see if everything adds up in terms of quality and quantity. The payment is then given to the supplier.

Stage 6: Receive and audit

Once all the paperwork is finalised, the vendors will then deliver the materials to the business. Then it falls to the business to perform a full audit of the inventory to make sure that everything that was ordered has been delivered. This is also when you would check for quality-control before moving forward.

Stage 7: Maintain a proper record

At the end of the procurement process, it is very important to thoroughly organise and keep track of all your purchases, invoices and orders placed with vendors, so that you have an easy reference system for future audits.

‘‘

The procurement process is a delicate balance of various networks and individuals, that being the case, it needs a watchful eye.

Some Key Tips For More Efficiency

Keep re-negotiating contracts

Even after having signed the contracts with vendors, try to keep negotiations open, because the best way to make the most of it is to keep with the current market trends. Market trends can be wildly unpredictable at times and are constantly changing, so are the demands of consumers. It is your job as the provider of the product or service to ensure that those needs are being met. To stay current with these changing trends and changing needs re-negotiations are a must.

Do regular assessments

While it is good to build a strong working relationship with vendors, the business’s needs must always come first. That said, you need to do regular assessments of your current vendors and suppliers to see if they are meeting the standard you expect in terms of delivery schedules and quality of materials. It also helps to take that data and make a comparison with other vendors’ performances to see which is doing better. If your current vendor fails to meet the requirements you either have to reassess the contract or change sources.

Automate as much as possible

In the age of digitalisation, your business would greatly benefit from making use of the things it has to offer. Automating the majority of your procurement processes from invoicing, supplier enquiries, reviews, updates, and delivery schedules will greatly improve the overall performance of the process. Much of this can be achieved by using a procurement software.

A procurement software is simply a management platform that allows the organisation complete visibility into all the stages, tasks and activities needed to maintain a smooth workflow. It can also help do regular assessments and update you on the same.

Though all this might seem like a massive process, it is just one small part of a larger system of moving products and services through the body of business. Once you understand the bigger picture things become clearer. Go check out our article on ‘supply chain management’ for that big picture!